I rarely share anything about my daily working life here. It’s almost like a double life I live. (Although I did share about working in Zhangjiang (张江) before.) But here’s perhaps something cool to share; how Pimax’s electronics are made, and for that matter, many of the world’s stuff.

Last Tuesday, with a colleague, I traveled to Longyou (龙游) which is part of Quzhou (衢州) in the Zhejiang province. After a two-hour trip on the high-speed train from Shanghai, and then a 30-minute drive, we arrived at Longyou’s high-tech park. It’s similar to Zhangjiang, in that a lot of tech companies are hurdled together, I’m sure in part due to some investment from the local government. A key difference with Zhangjiang is that here it’s factories rather than R&D and marketing.

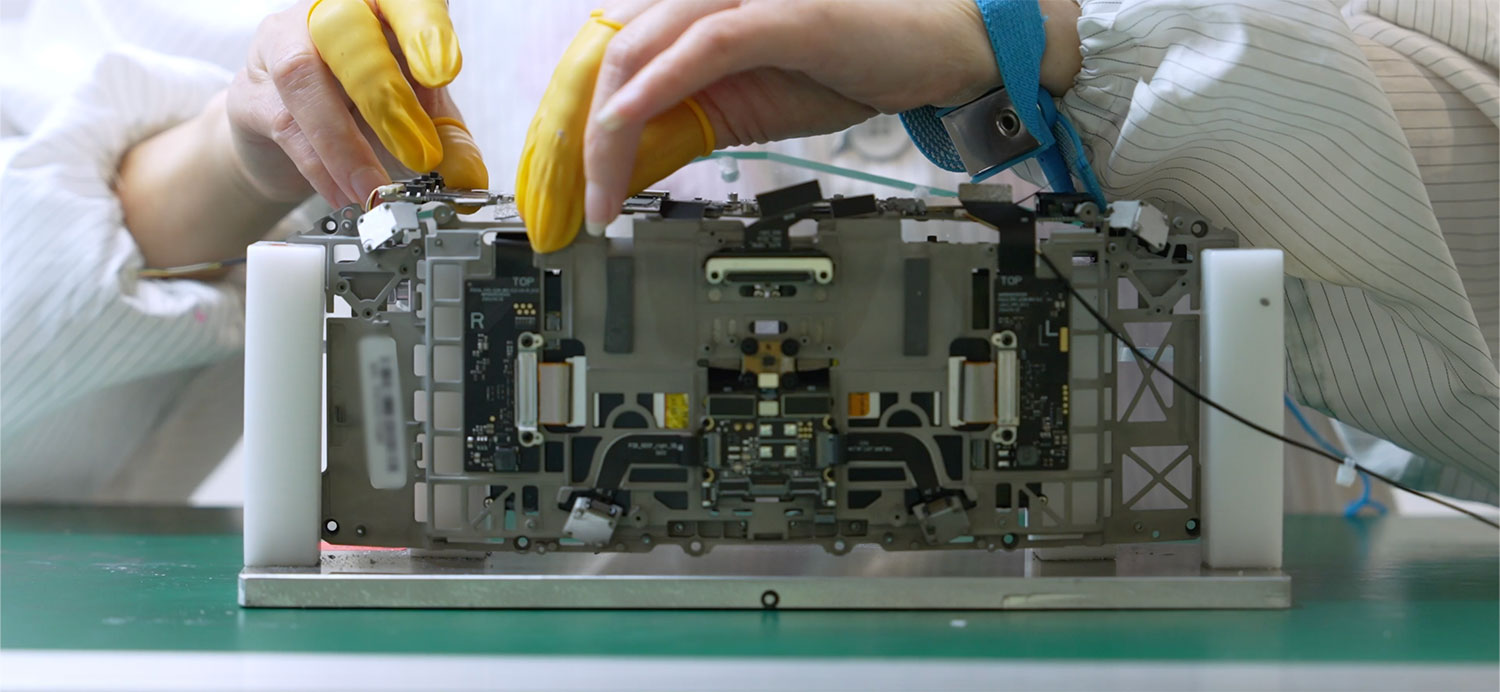

Pimax’s virtual-reality headsets factory is pretty large, built for growth. (Plus the roof is fully covered in solar panels.) These aren’t like the dingy factories that exist in many people’s stereotypes about China. The factory is clean, well-organized, brightly lit and air-conditioned. There’s an exhibition area on the ground floor, with upstairs a small office, an assembly line, and a warehouse. To even enter the assembly area, you need to wear dust-proof and anti-static clothing, and enter through a dedusting tunnel — where ventilators blast the dust off your body. That’s for the main assembly line. There’s also an ultra-clean dust-free room for the lens assembly. There, the clothing covers your full body. Only your eyes are not covered.

I also visited some clothing factories in 2019, and it felt similar, in that the staff was taken well care of. Each employee is responsible for each step, with clear documentation on how to do it just above their workplace. They don’t do crazy shifts and they’re treated as part of a team by their managers. But aside from some small talk, we had to rush to get the filming done in one day, the result of which you can see here.